Germany, Norwegian Register of Shipping(DNV·GL)

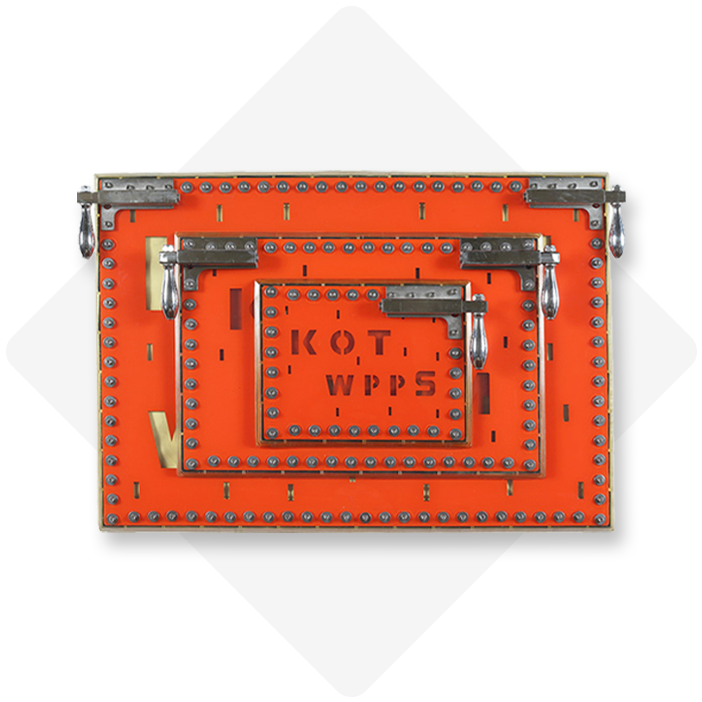

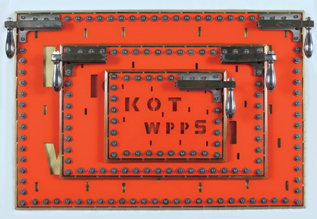

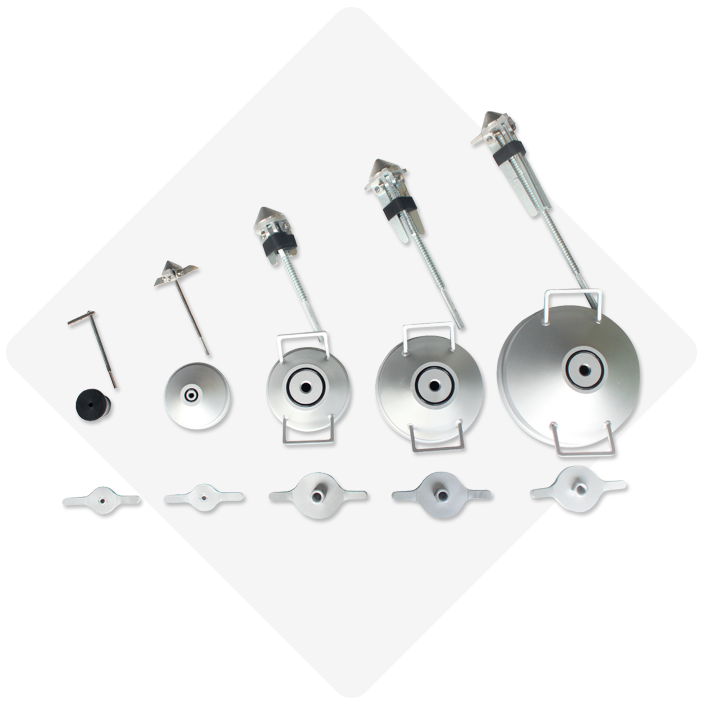

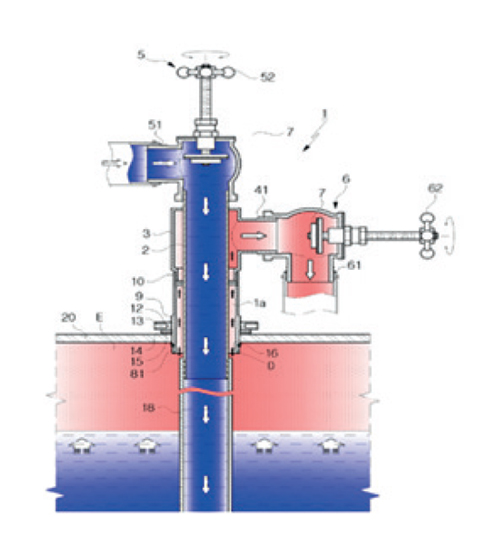

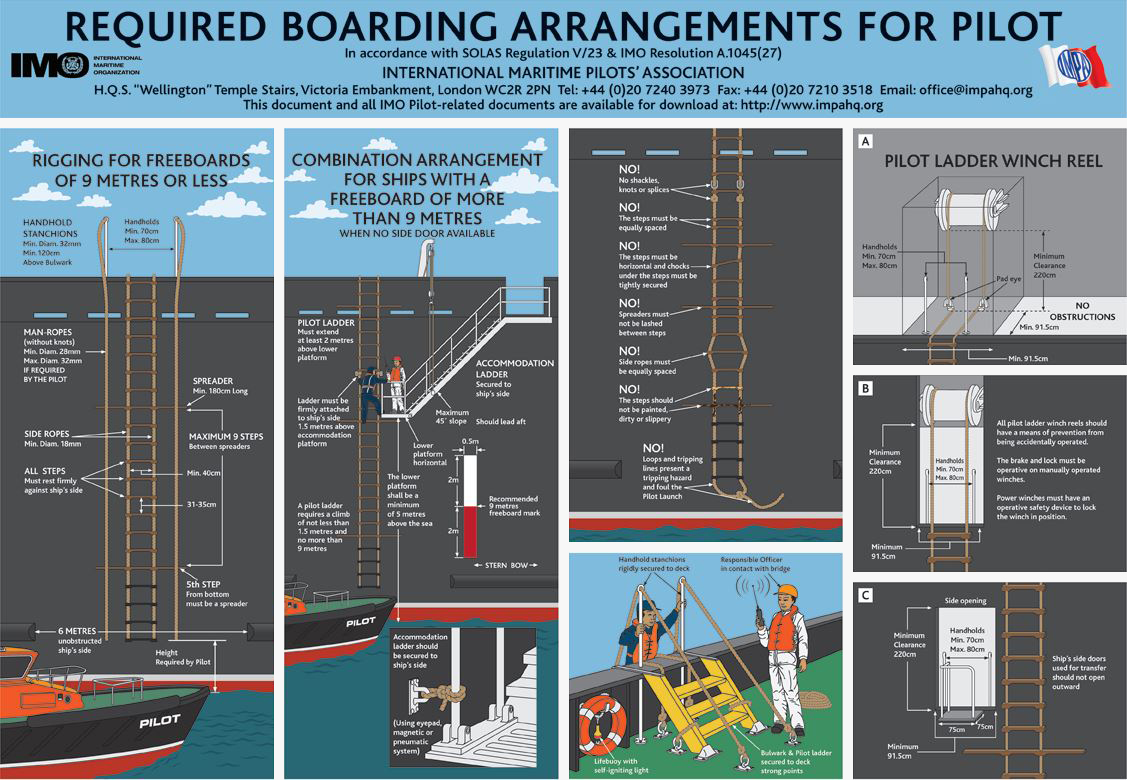

Pilot Ladder Fixing Equipment RPLF-900

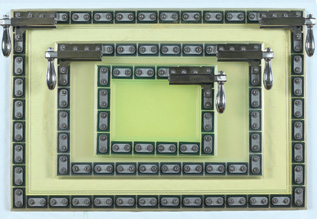

Accommodation Ladder Fixing Equipment RALF-2000 Performance Certification Test

Selected as "National Representative Innovative Companies 1000"

Received the Excellence Award at "2020 Oceans and Fisheries Technology Commercialization Show"

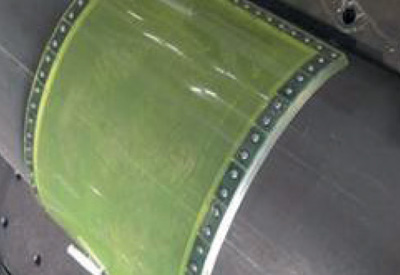

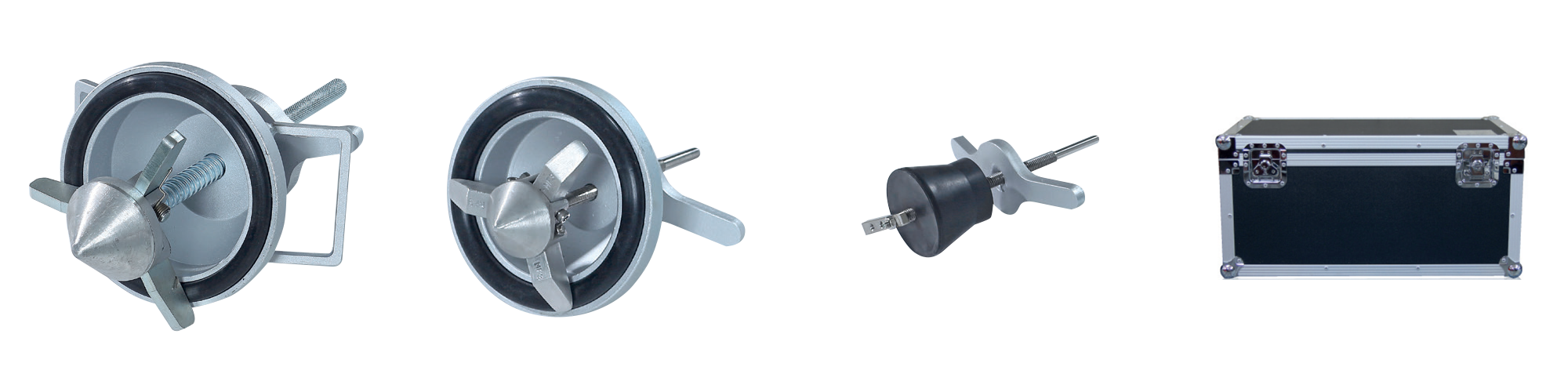

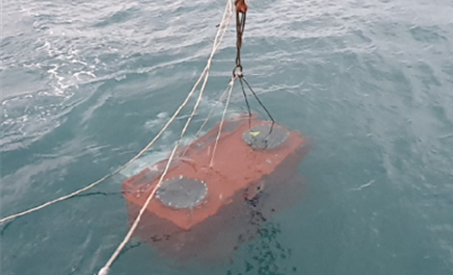

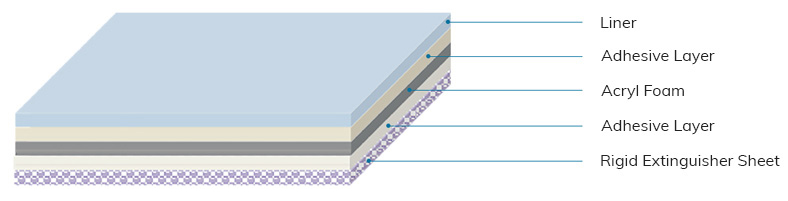

Supplied Water Proof Pad Against the Damaged Hole to Yeosu/Ulsan Coast Guard

Supplied Water Proof Pad Against the Damaged Hole to Korea Coast Guard Special Rescue Unit in Busan

Germany, Norwegian Register of Shipping(DNV·GL)

Pilot Ladder Fixing Equipment RPLF-900 Performance Certification Test

Supplied Water Proof Equipment Against the Damaged Hole to Naval Speed Boat

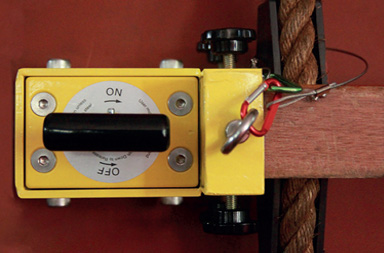

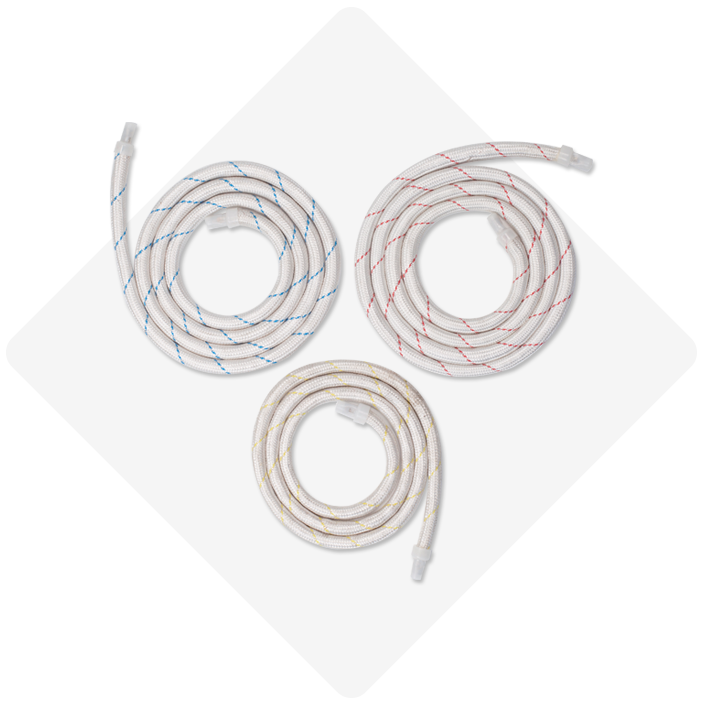

Patent for "Cable Connections with Fire Extinguishing Function"

Supplied Water Proof Pad Against the Damaged Hole to Hansando Warship of Korean Navy

Selected as "2020 Ace Stella Company 10" in Busan City 07. Patent for "Cable Connections with Fire Extinguishing Function"

Supplied Water Proof Pad Against the Damaged Hole to Daejoyeong Warship of Korean Navy